Dry Running in Pumps and Precautions

Dry Running in Pumps

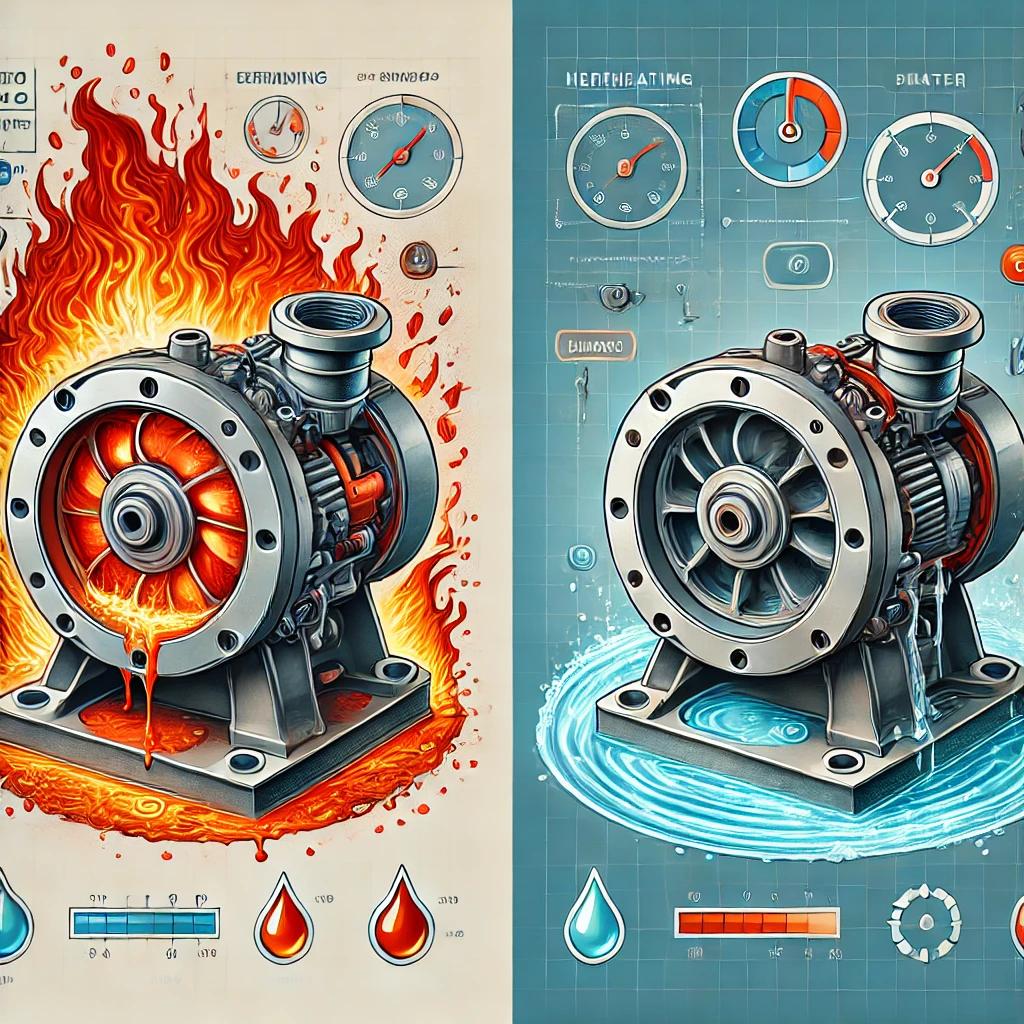

If a pump lacks water inside, there is no resistance to slow the impeller's rotation. This causes the pump's shaft and other components to overheat. Overheating can lead to melting at the parts where the impeller contacts the shaft, causing the impeller to stick and preventing the shaft from rotating. For this reason, even a short period of dry running can be highly detrimental. It is essential to ensure that the pump is primed and contains sufficient liquid before starting.

The fluid around mechanical seals creates a protective film that prevents damage. Without this film, the temperature rises quickly, leading to thermal cracks on the seal surface. Water plays a vital role as a coolant, and in its absence, the impeller’s temperature increases much more rapidly, resulting in significant wear and deformation.

During dry running, larger pumps with heavier impellers deform more quickly compared to smaller models. However, stainless steel pumps are more durable than plastic ones. Modern pump systems are equipped with smart control panels that include low-current protection. When a pump runs dry, it draws minimal current, which is detected by the control system, triggering an automatic shutdown to prevent damage. These intelligent systems ensure pumps avoid dry running, preserving their functionality and reducing maintenance costs.

Proper maintenance of pump systems is the key to preventing dry running. Regularly checking water levels, ensuring the pump is primed before operation, and testing protection mechanisms extend the lifespan of the pump and enhance its efficiency.