Fire Pump Operation Under Negative Suction Conditions – TS EN 12845 Standard

Fire Pump Operation Criteria Under Negative Suction Conditions According to TS EN 12845 Standard

In facilities with a high fire risk, such as parking garages, warehouses, factories, and fuel stations, hydrant and sprinkler systems must be installed to ensure fire safety. These systems require a large amount of stored water (exceeding 100 m³). In metropolitan areas, where space is limited, underground water tanks are often used for storage.

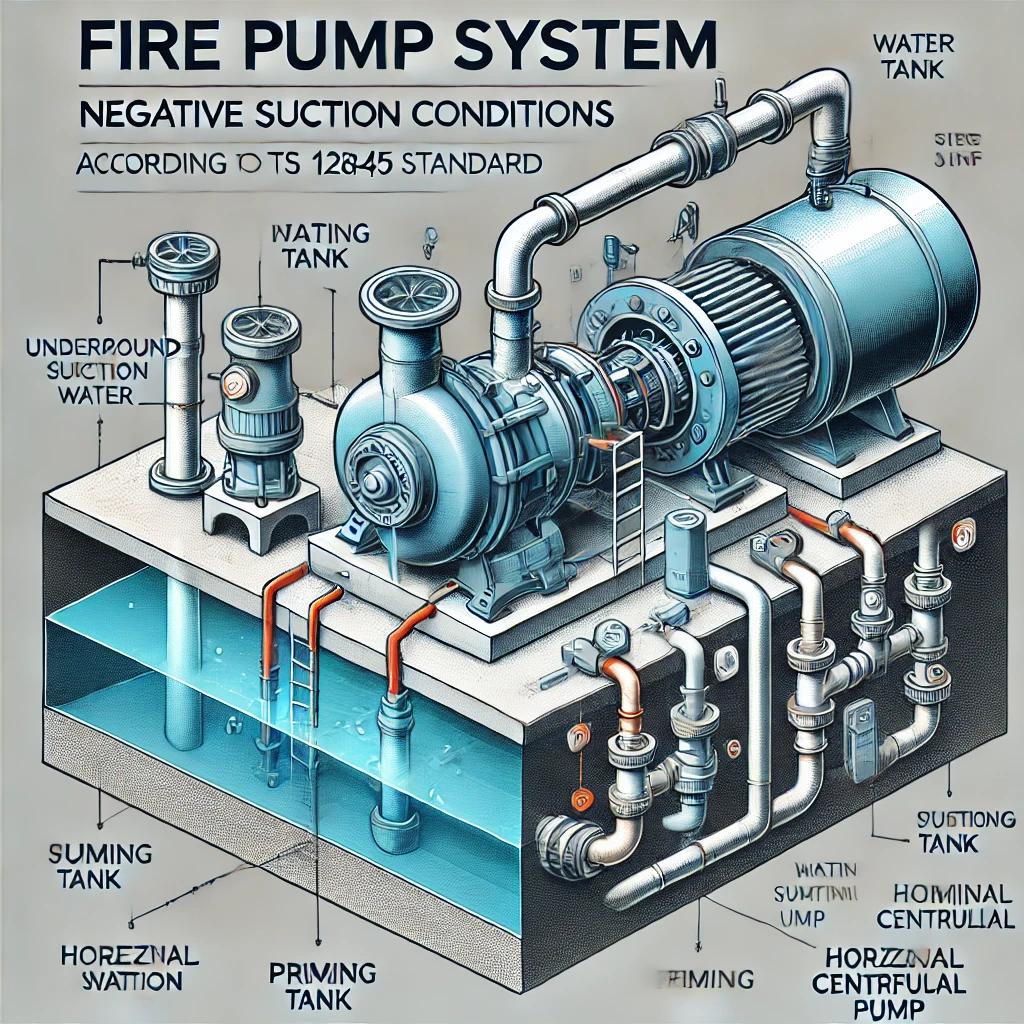

According to the TS EN 12845 standard, when underground suction (negative suction) conditions apply, the use of either a turbine-type pump or a horizontally mounted centrifugal pump is recommended. However, turbine-type pumps are more costly and pose maintenance challenges. On the other hand, horizontal centrifugal pumps, with a back pull-out design, allow easy access to the impeller without dismantling the piping system. Split-case pumps offer similar advantages by allowing the upper casing to be separated from the lower casing.

When horizontal centrifugal pumps are installed for underground suction, an additional priming tank must be incorporated into the system, unlike in above-ground suction conditions.

Importance and Use of Priming Tanks

Depending on the fire risk of the building, each pump must have a priming tank with a capacity of at least 100 to 500 liters. These tanks (See Figure A, B, part 3) must be installed at a level above the pump suction line. They are supplied from both the pump discharge line and the main water network and are equipped with automatic level monitoring. If the water level drops below a certain threshold, an audible and visual alarm is activated. A direct connection from the bottom of the tank to the pump suction line prevents air from entering the system and ensures the pump can start immediately in case of fire.

Using a priming tank for each pump operating under negative suction conditions prevents the suction line from running dry, enhancing fire safety.

Key Considerations for Fire Pump Systems Under Negative Suction Conditions

-

The suction lines of the main, backup, and jockey pumps must be connected separately.

-

Ideally, pumps should be mounted directly above the water tank, with the shortest possible suction line and only one elbow connection.

-

The suction line should include an eccentric suction kit that is at least twice the diameter of the pump inlet.

-

The suction line diameter must be at least DN80, and water velocity should not exceed 1.5 m/s at maximum flow rate.

-

When determining the suction line diameter, factors such as straight pipe and fitting losses, site elevation above sea level, evaporation losses at maximum water temperature, and the NPSH value of the pump at maximum flow must be considered. (The suction depth should not exceed 3.2 meters from the pump suction axis.)

-

Pump power must be selected based on the maximum capacity of the determined hydraulic curve.

This ensures optimal performance and long-term reliability of the fire pump system under negative suction conditions.