How to Install a Booster Pump? Operating Guide

2025-01-21 23:20:11

How to Install a Booster Pump? Operating Guide. Comprehensive guide on hydrofor installation and operation: suitable liquids, pipe connections, electrical setup, and pre-operation instructions.

Hydrofor Installation and Operation Guide

Hydrofor Units:

Used in industrial and agricultural sectors, as well as in homes, apartments, factories, industrial complexes, resorts, and water treatment systems, to provide pressurized water.

Not Suitable for the Following Liquids:

- Liquids containing abrasive materials

- Liquids containing solid or fibrous objects

- Flammable and explosive liquids

Installation

- Safe Handling: Always lift and move the hydrofor unit using slings for safety.

- Protection: Protect the device from external weather conditions and freezing.

- Airflow: Ensure that the cooling airflow through the fan cover openings is not obstructed.

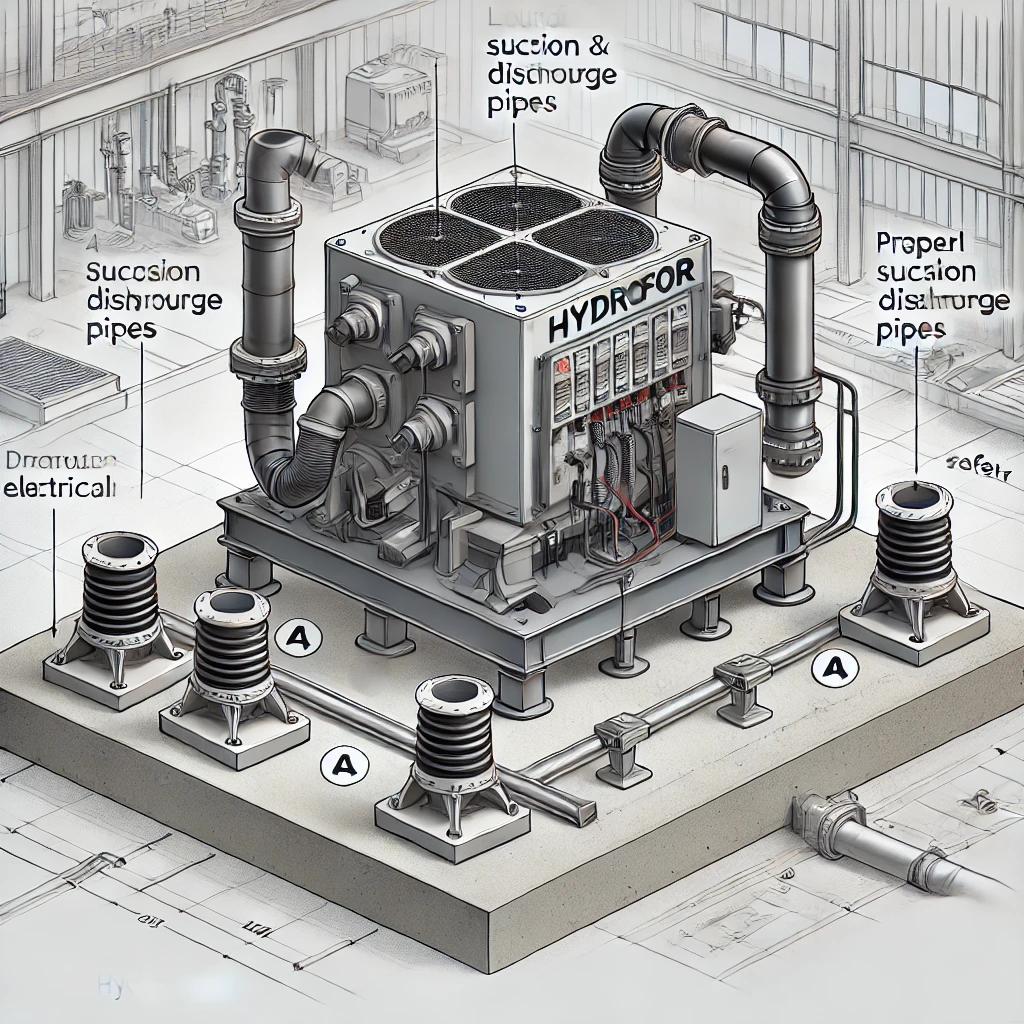

- Placement: Place the hydrofor on a flat concrete surface using the 4 rubber mounts provided. Larger industrial hydrofors should be securely anchored with appropriate bolts and dowels.

Suction and Discharge Pipes

- Pipe Durability: Pipes must withstand the maximum pressure of the hydrofor.

- Suction Pipe Specifications: Ensure proper sealing and that the suction pipe is at least the same diameter as the hydrofor collector or pump inlet.

- Installation Slope: Keep the suction pipe as short as possible, with a single elbow, and installed with a 1-2% upward slope toward the pump.

Incorrect slopes create air pockets, preventing the pump from operating.

- Check Valve Usage: Avoid using check valves on the pump discharge side. Malfunctioning valves cause frequent activation, indicating the need for maintenance.

- Multi-Pump Systems: In multi-pump systems, using a shared suction collector is highly problematic. Each pump should have its own suction line.

Starting Operation

Electrical Connection:

Hydrofor units are powered by single-phase or three-phase motors that comply with European standards. Connections should only be made by certified electricians or technical service providers.

- Grounding: Ensure the device is grounded before operation.

- Control Panel: Multi-pump three-phase hydrofors come with control panels including switches, contactors, thermals, and phase protection relays.

Pre-Operation

- Filling the Suction Pipe: Before trial operation, fill the suction pipe and pump with water.

- Float Switch Adjustment: Adjust the float switch according to the tank size and connect it.

- Pump Rotation Check: Verify that the pump rotation direction is correct.

- Based on Water Level:

- If the water level is above the hydrofor, close the discharge valve, remove the fill plug, open the suction valve, and wait for water to appear. Then close the plug.

- If the water level is below the hydrofor, open the fill plug and use a funnel to fill the suction pipe and pump with water. Then close the plug.

Note: Adjust the float switch to match the tank size.