Hydrofor Pressure Calculation Guide | Hm (mWC) and Practical Example

Calculation of Hydrofor Pressure Hm (mWC)

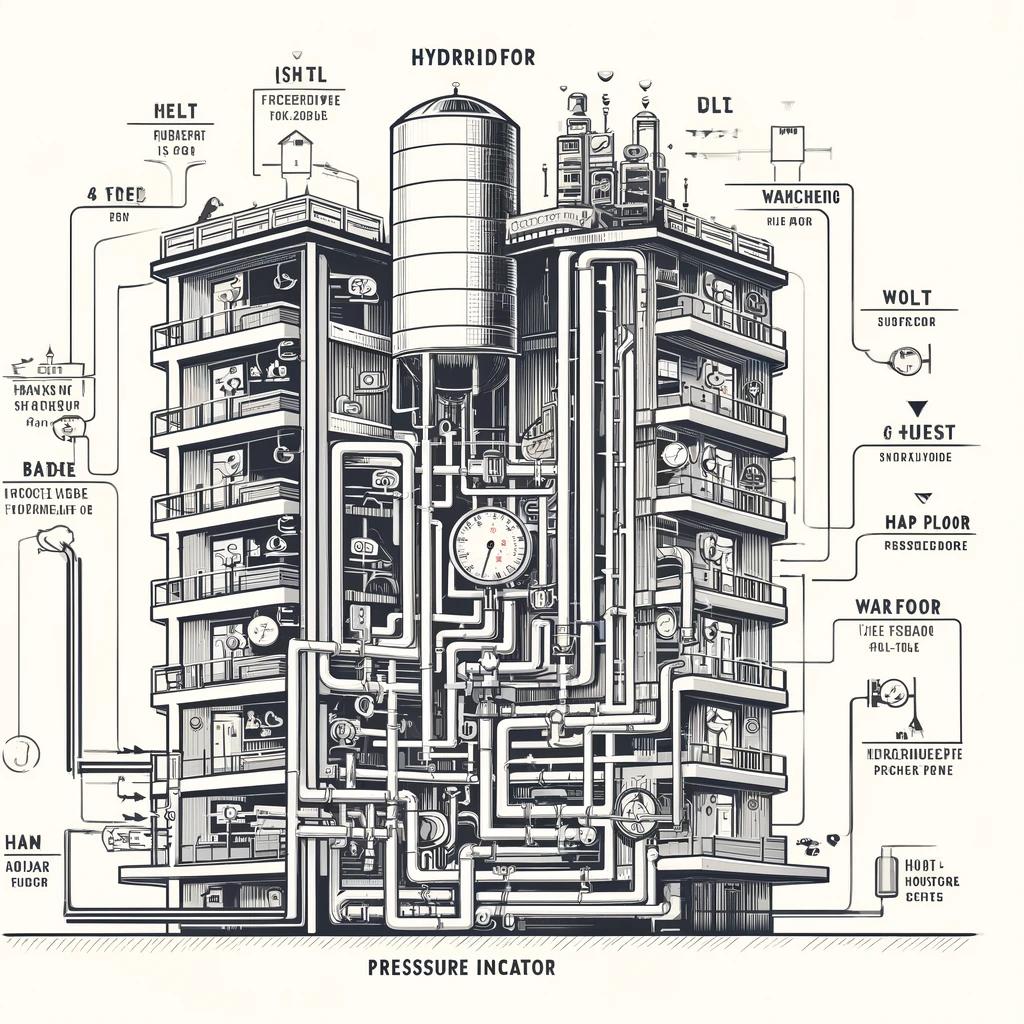

The hydrofor outlet pressure is the sum of the pre-pressure coming to the hydrofor suction collector and the pressure generated by the hydrofor. In Turkey, since hydrofor systems typically use an open-to-atmosphere water tank at the same level as the hydrofor, the pre-pressure of the water is negligible. When determining the hydrofor outlet pressure, the distance between the hydrofor location and the farthest water consumption point on the top floor of the building is called the critical line. The hydrofor is selected to provide 10-15 mWC flow pressure at the last user on this critical line. Accordingly;

Hm : h + ΣΔp + 15 (mWC)

-

Hm: Required minimum hydrofor pressure (mWC)

-

h: Building static height (elevation difference) (mWC)

-

ΣΔp: Total transmission losses (mWC)

-

15 (mWC): Working pressure (flow pressure)

The pressure calculated with Hm is accepted as the lower pressure point (Halt) where the hydrofor starts operating. Hydrofor systems work with a balance tank where the water pressure fluctuates between Halt and Hüst. A pressure switch controls the activation and deactivation of the hydrofor pumps based on these pressures.

-

Hüst: Halt + 15 (mWC)

-

For three-pump systems: Hüst = Halt + 20 (mWC)

Calculating total transmission losses (ΣΔp) requires detailed information about pipe diameters, lengths, elbows, valves, and fittings along the critical line. However, this may not always be feasible. Therefore, assuming 20-25% of the building's static height as total transmission loss is a practical and safe approach.

Sample Calculation

For a building with a static height of 42 m (approximately 14 floors), the hydrofor pressure is calculated as follows:

Hm = 42 x 1.25 + 15 = 67.5 mWC

Hm = Halt = 67.5 mWC

Hüst = Halt + 20 = 87.5 mWC

In this case, a hydrofor system with a capacity of Q = 18 m³/h, Hm = Halt = 67.5 mWC, equipped with 2 or 3 pumps, would be suitable and compliant with DIN standards.

Note: The static water pressure within the building installation should not exceed 5 bar (50 mWC) at any point. In areas where the pressure exceeds 5 bar, pressure-reducing valves (regulators) or zoning of the installation should be implemented.