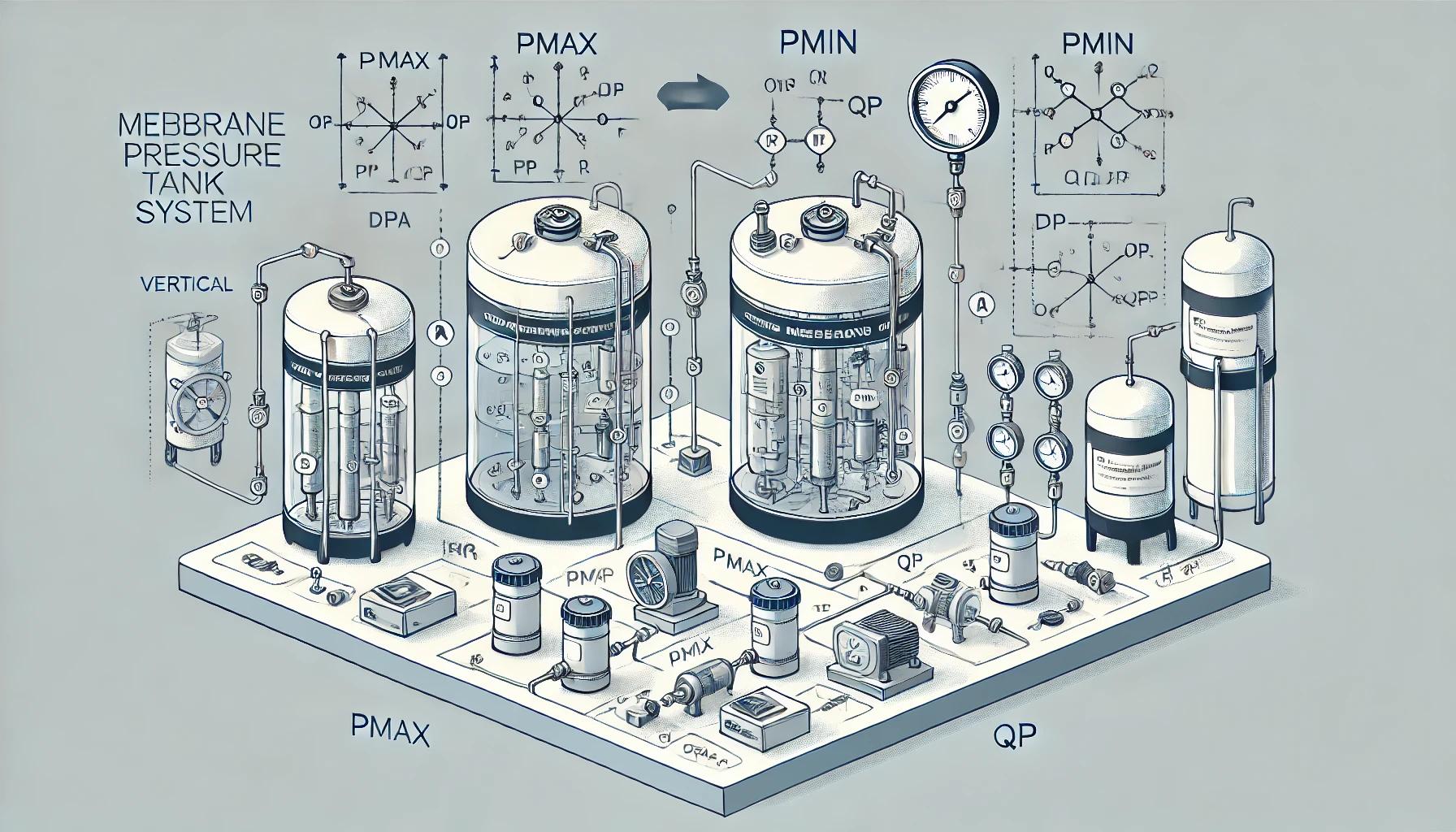

Membrane Tank Volume Calculation: Accurate Formulas and Examples

Membrane Tank Volume Calculation (Vmt)

The following calculation method is used to determine the required volume for vertical or horizontal tanks. In volume calculations, only one of the main pumps in the booster set is considered. Proper volume calculation is essential to extend pump lifespan and ensure energy efficiency. Therefore, keeping the motor switch frequency under control allows for a more stable and long-lasting operation of the system.

The permissible number of motor starts per hour, pump flow rate, and pump operating pressure relationships must be identified. With accurate calculations, the correct membrane volume can be determined to ensure efficient system operation. Volume calculations should be done precisely to prevent excessive pressure fluctuations and maintain balanced pressure within the system.

Formula:

Vmt = Membrane pressure tank volume (m3/h)

Qp = Average pump flow rate (m/h) (Qmin + Qmax/2 = Qp)

Pmax = Maximum pressure setting (mSS)

Pmin = Minimum pressure setting (mSS)

Z = Permissible motor start frequency per hour

Example Calculation:

For 2 KO 25-8/75 Booster;

- Pmax. = 82 mSS

- Pmin. = 60 mSS

- Qmax. = 25 m3/h

- Qmin. = 17 m3/h

- Z = 40 (found from the table)

By calculating the average pump flow rate, the membrane tank volume can be determined. Accurate calculations ensure long-lasting and efficient system operation. The required tank volume may vary depending on the application and requires professional assessment.