Protection & Control Panels: Selection and Usage Guide

2025-01-21 23:14:17

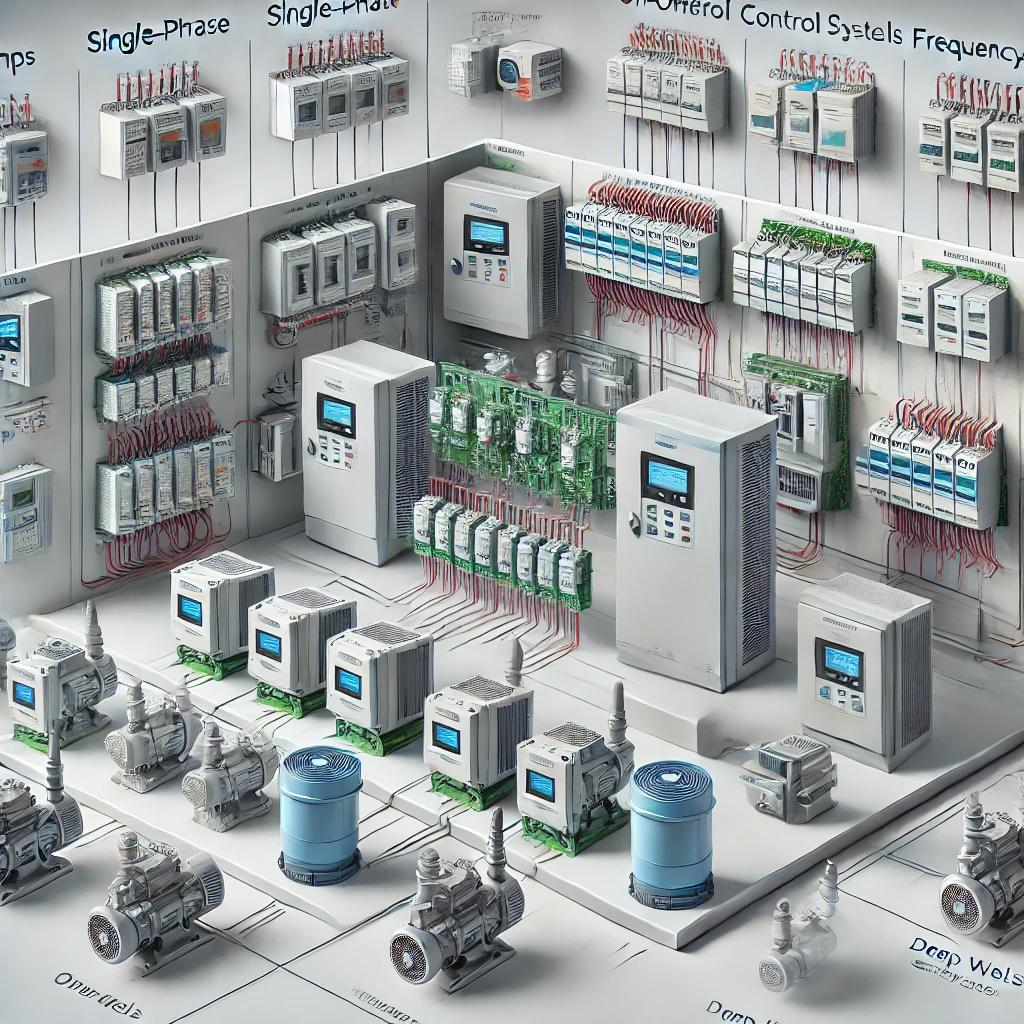

Protection & Control Panels: Selection and Usage Guide. Comprehensive guide on choosing, functions, and applications of protection and control panels. Panels tailored for specific applications.

How to Select Protection & Control Panels

When choosing protection and control panels, consider the following criteria:

-

Pump Electrical Supply:

- Select panels compatible with single-phase or three-phase systems.

-

Pump Control Logic:

- Determine whether a standard on-off system panel or a frequency-controlled panel with a driver is needed.

-

Electrical Capacity:

- Ensure the panel can handle the electrical power of the pumps in the system. For example, if the pump power is 5.5 kW, the panel should support pumps with at least 5.5 kW or higher capacity.

-

Number of Pumps:

- Choose between single or dual panel systems based on the number of pumps.

-

Application Type:

- Select panels designed for specific applications like HVAC, deep well, drainage, or hydrofor systems.

-

Building Automation Integration:

- Assess whether system status and fault information can be monitored through building automation systems.

-

External Control Signals:

- Check if the panel supports external control signals like 4-20 mA or 0-10 V.

What Do Protection & Control Panels Do?

Protection and control panels:

- Enable automatic operation (start-stop) of pump and hydrofor systems.

- Prevent mechanical and electrical damage by avoiding dry running or frequent start-stop cycles.

What Are Protection & Control Panels?

Electrical control panels designed to automate pump systems and protect them from potential mechanical and electrical damage.

Where Are Protection & Control Panels Used?

- Hydrofor Systems: For pressurized water supply.

- Drainage and Wastewater Systems: For septic and similar applications.

- Fire Fighting Systems: For controlling and protecting fire pumps.

- Deep Well Systems: For deep well pump applications.

- HVAC Systems: For heating, ventilation, and air conditioning.

- Industrial Pump Systems: For factory and industrial pump systems.