What is a Booster Pump? Selection Criteria and Pump Types

What is a Booster Pump System?

A booster pump system ensures a continuous and comfortable water supply in situations where the city’s water pressure is insufficient. It is commonly used in high-rise buildings or places with water storage tanks to handle water shortages. The system consists of a pump and auxiliary control equipment.

Auxiliary Equipment of a Booster Pump System:

- Pressure tank (expansion tank) and connection flex hose

- Level float switch

- Electronic control panel

- Pressure switch

- Manometer

- Ball valve

- Check valve

- Suction and discharge manifolds (for multiple pumps)

What are the Criteria for Selecting a Booster Pump?

To ensure long-term efficiency, the correct type and capacity of the booster pump must be selected. Key factors include:

- Location of the water tank relative to the pump: Negative suction scenarios must be evaluated.

- Water quality: Consider temperature, contamination, hardness, and pH levels.

- Installation area characteristics: Check for adequate space, ventilation, and noise levels.

- Power supply type: Verify single-phase or three-phase compatibility.

- Flow rate calculation: Base the flow rate on the type of building (school, hotel, residence, etc.), the number of users, and simultaneity factors.

- Pump efficiency: Select pumps operating at their most efficient point to reduce electricity costs.

- Required pump pressure: Account for static height, total transmission losses, and operational pressure.

- Pressure tank size: Properly calculate the volume and pressure rating of the tank.

- Flow variability: In systems with fluctuating flow, consider multiple pump systems or frequency-controlled boosters for optimal performance.

This approach ensures energy efficiency and reliability, even during pump malfunctions, as the system can continue operating.

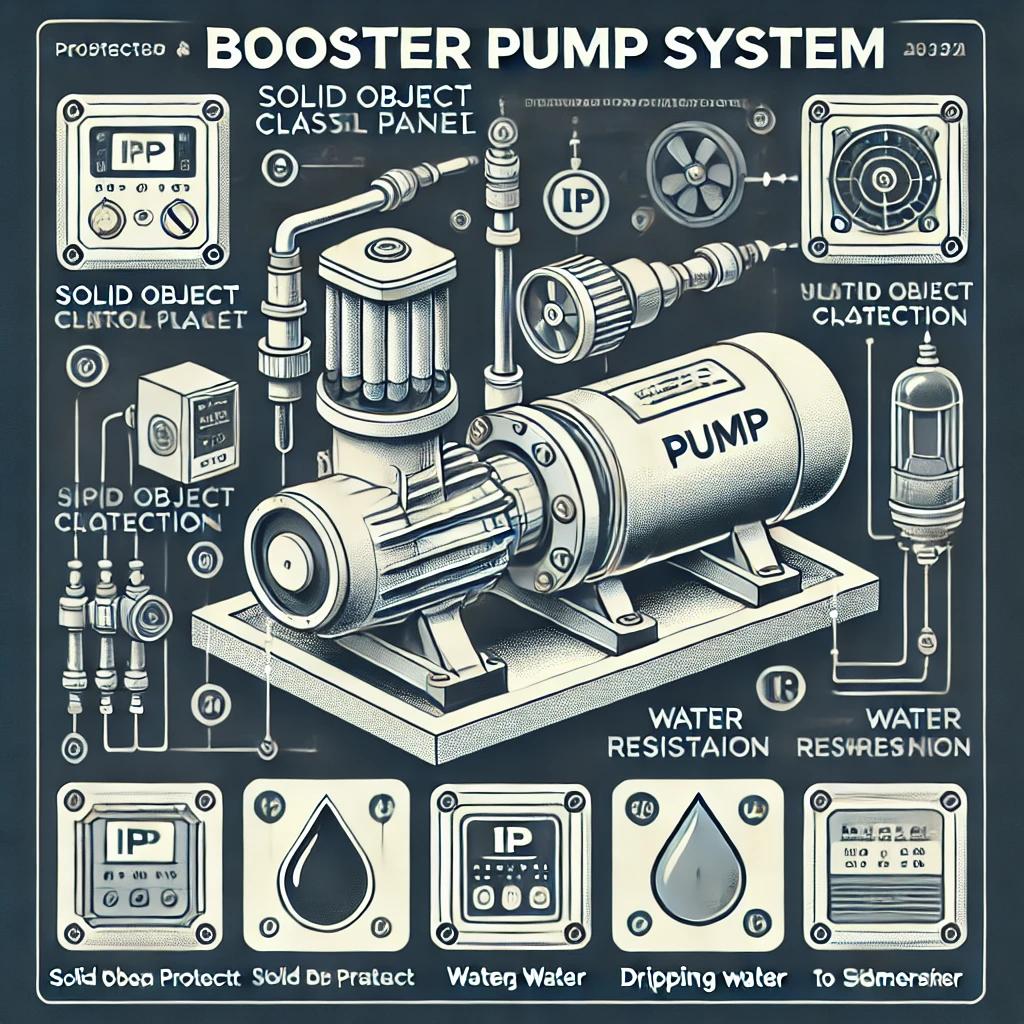

What is the IPXY Protection Class?

The IP protection class indicates the degree of protection electrical equipment offers against dust and water. It is represented as IP XY, where:

- X: Protection against solid objects

- Y: Protection against water

Protection Levels for Solid Objects:

- 0: No protection

- 1: Protection against objects >50 mm

- 2: Protection against objects >12.5 mm

- 3: Protection against objects >2.5 mm

- 4: Protection against objects >1 mm

- 5: Dust-protected

- 6: Dust-tight

Protection Levels for Water:

- 0: No protection

- 1: Dripping water

- 2: Dripping water at 15° angle

- 3: Spraying water at 60° angle

- 4: Splashing water

- 5: Water jets

- 6: Heavy sea waves

- 7: Immersion in water

- 8: Submersion under water

Advantages of Wet Rotor vs. Dry Rotor Pumps in Heating Systems

Pump selection in heating systems depends on the design requirements. Generally:

- Use dry rotor pumps when flow exceeds 70 m³/h or pressure exceeds 15 mss.

- Use wet rotor pumps for lower flow and pressure requirements.

Advantages of Dry Rotor Pumps:

- Operates with aggressive water containing impurities like lime

- Can be installed in a vertical position

- Wide product range available

Advantages of Wet Rotor Pumps:

- Quieter operation

- Capability to operate on various hydraulic curves

- Lower maintenance costs due to the absence of mechanical seals