What is Legionella? Symptoms, Risks, and Prevention Methods

Legionella and Legionnaires' Disease

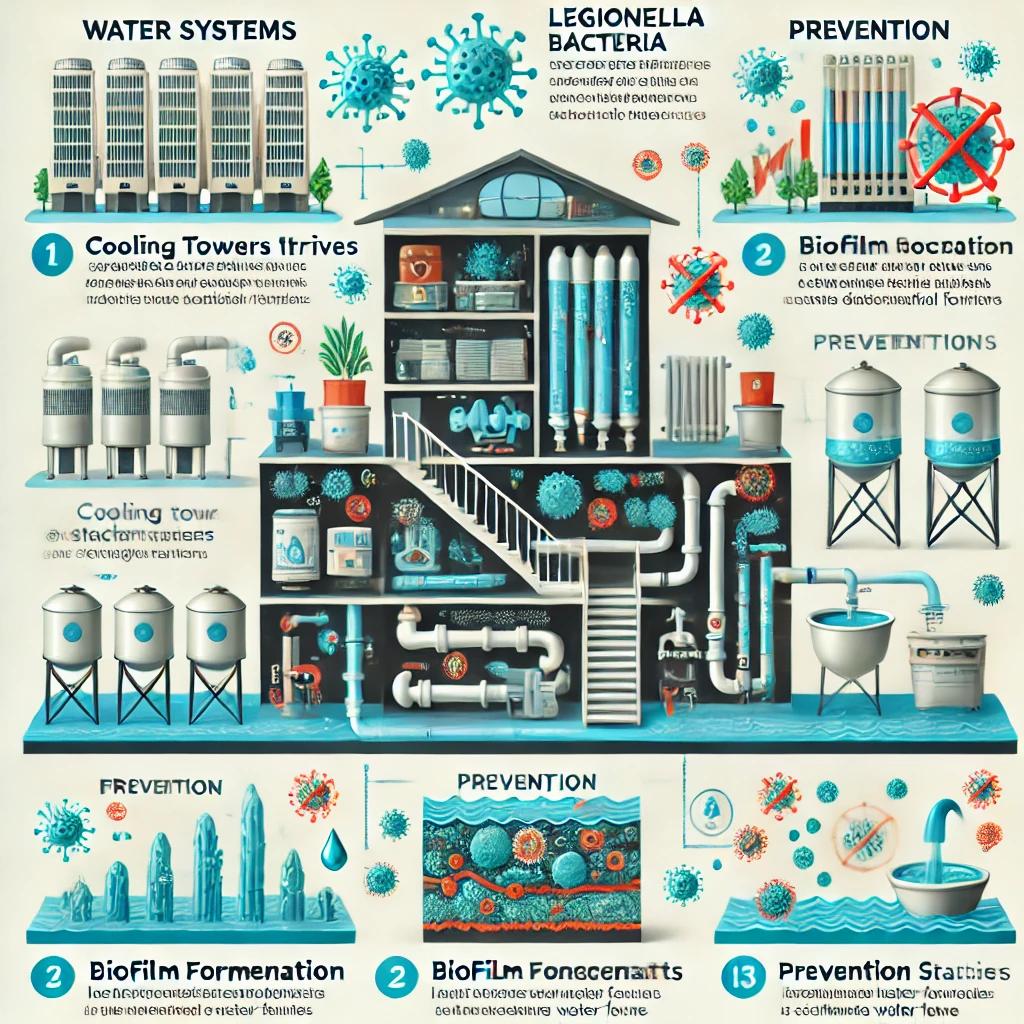

Legionella pneumophila, commonly known as Legionella, is a bacterium that thrives in industrial water systems and can rapidly proliferate. When inhaled, it can cause Legionnaires' disease, a severe lung infection with symptoms similar to pneumonia, which can be fatal in some cases.

Environments and Conditions That Promote Legionella Growth

Various factors contribute to the spread of Legionella, including building water systems, biofilm formation, stagnant water, and the presence of solid particles.

1. Building Water Systems

Legionella can easily grow in the following water systems:

-

Hot and cold water distribution networks

-

Spa tubs and thermal baths

-

Misting systems

-

Decorative fountains and pools

-

Cooling towers

Without an appropriate Legionella management plan, these systems can become ideal breeding grounds for the bacteria, posing a significant health risk.

2. Biofilm Formation

Biofilm is a sticky layer formed by microorganisms in moist environments. Factors affecting its development include:

-

Temperature and pH levels

-

Nutrient concentration for microorganisms

-

Water flow rate and system design

-

Pipe material and wear conditions

-

Sediment accumulation

Biofilm provides an optimal environment for Legionella and other bacteria to thrive.

3. Stagnant Water

Stagnant water is an ideal habitat for Legionella proliferation. Risk-prone areas include:

-

Storage tanks and decorative pools

-

Unused pipes and fixtures

-

"Dead ends" in plumbing systems with no water flow

Stagnant water supports biofilm formation and weakens the effectiveness of disinfectants.

4. Solid Particles (Sediments, Debris)

Sediments found at the bottom of cooling towers, tanks, and pipes absorb disinfectants, reducing their effectiveness and allowing Legionella to thrive. Proper filtration systems in industrial settings are essential for maintaining clean water.

5. Scale and Corrosion

Scale deposits and corroded metal surfaces create suitable conditions for biofilm growth. Scale buildup can slow down water flow, indirectly supporting Legionella proliferation.

6. Temperature Fluctuations

Legionella thrives best in temperatures between 25-42°C. Water system designs should minimize exposure to this temperature range to prevent bacterial growth.

7. Water Pressure Changes

Sudden changes in system pressure can dislodge biofilm, spreading bacteria throughout the water system and increasing contamination risk.

8. pH Levels

Disinfectants used to combat Legionella are most effective within a pH range of 6.5 to 8.5. Regular monitoring of water pH levels is crucial for effective disinfection.

Legionella Prevention Methods

1. Control Measures

To prevent Legionella contamination, an industrial water management team should be formed, and a Legionella control plan should be developed. Routine analysis and disinfection should be conducted regularly.

2. Heterotrophic Colony Count

This test measures the general bacterial level in water. High colony counts indicate potential Legionella risk and necessitate immediate testing.

3. Disinfection

Several methods can be used to eliminate Legionella bacteria, including:

-

Chemical disinfectants (biocides, chlorine, peracetic acid, chlorine dioxide)

-

Non-chemical methods (copper-silver ionization, thermal disinfection, ultraviolet, and ozone treatment)

Proper application of these techniques is essential for preventing Legionella proliferation and ensuring water safety.